Description

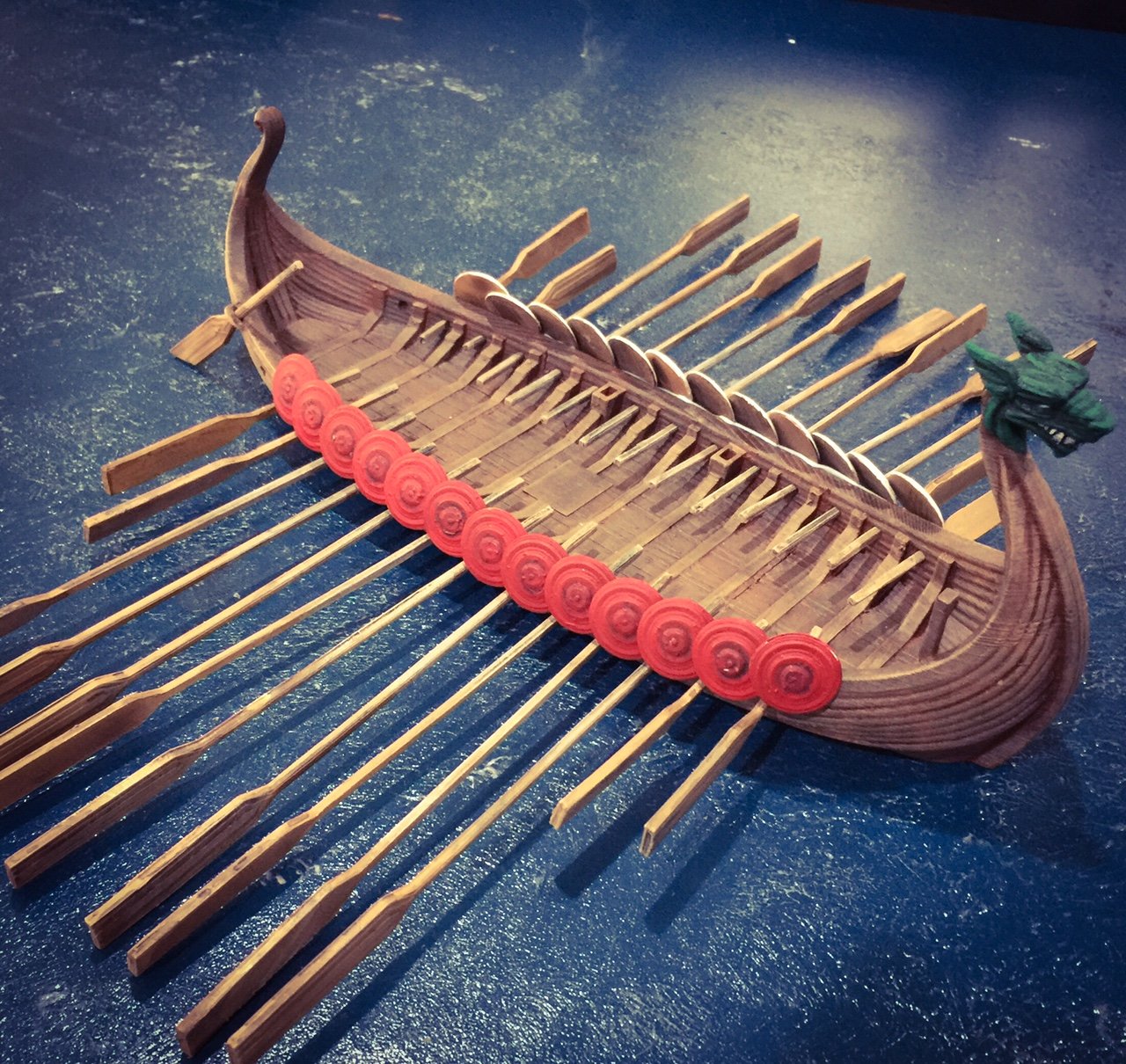

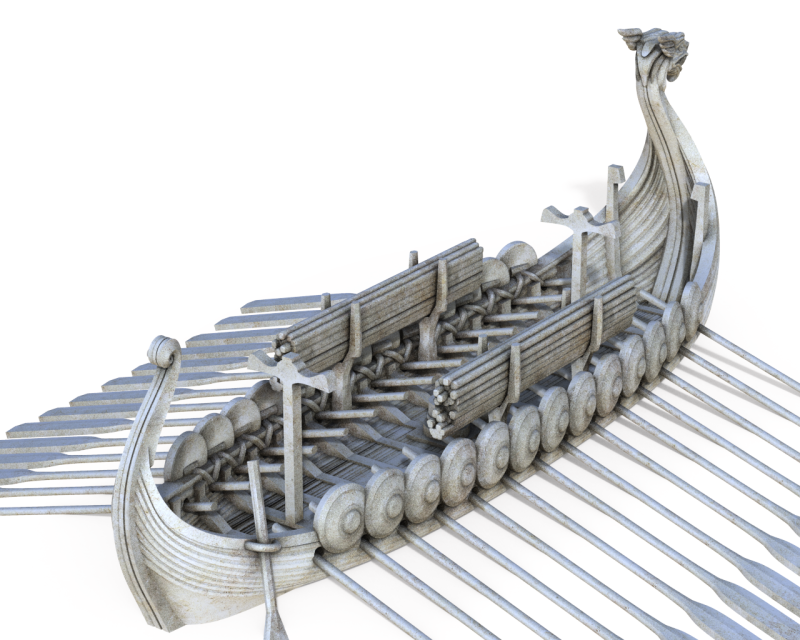

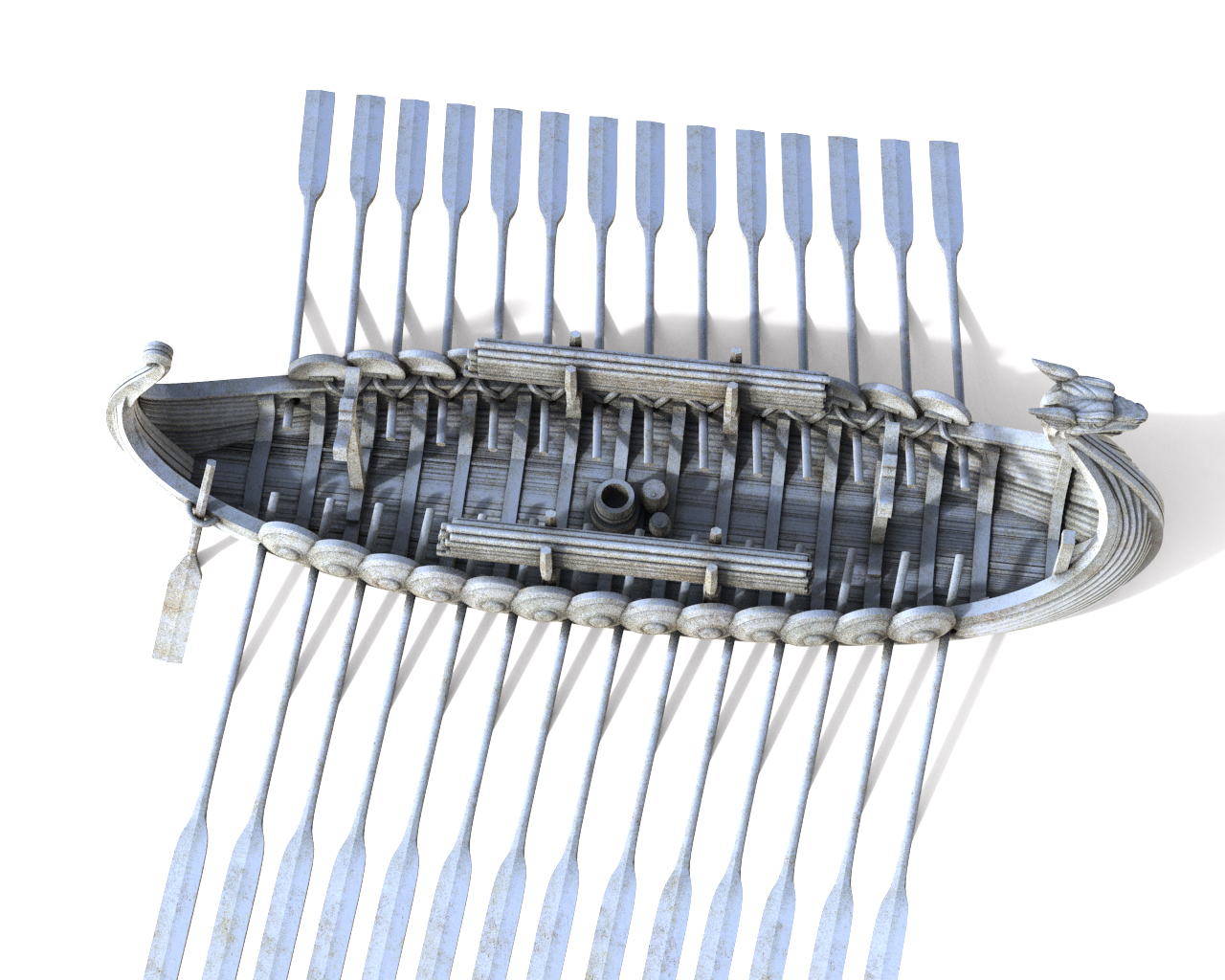

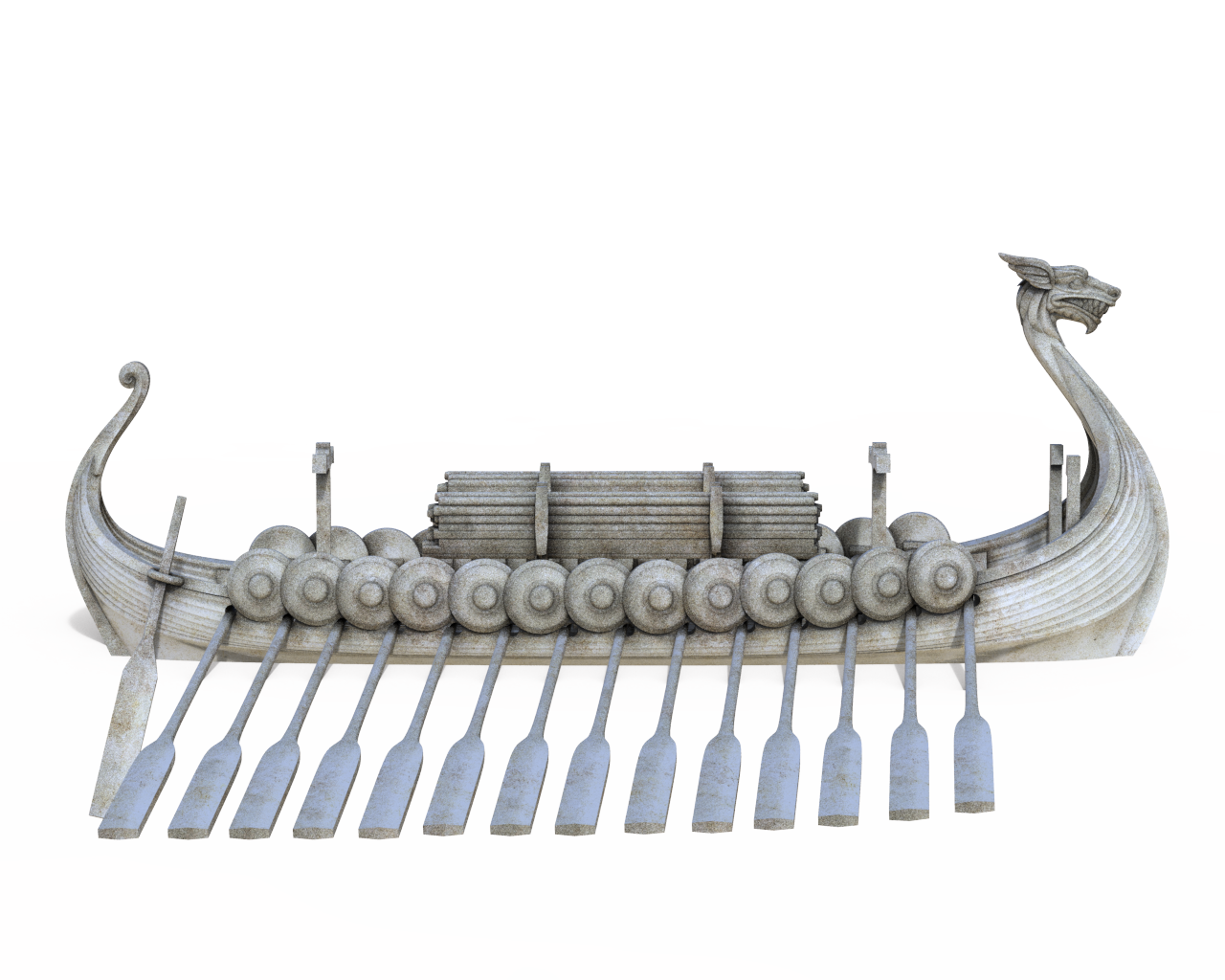

Proud sons of Odin crewed these sturdy vessels, using them to travel to far distant shores, to either raid or trade with those who lived there.

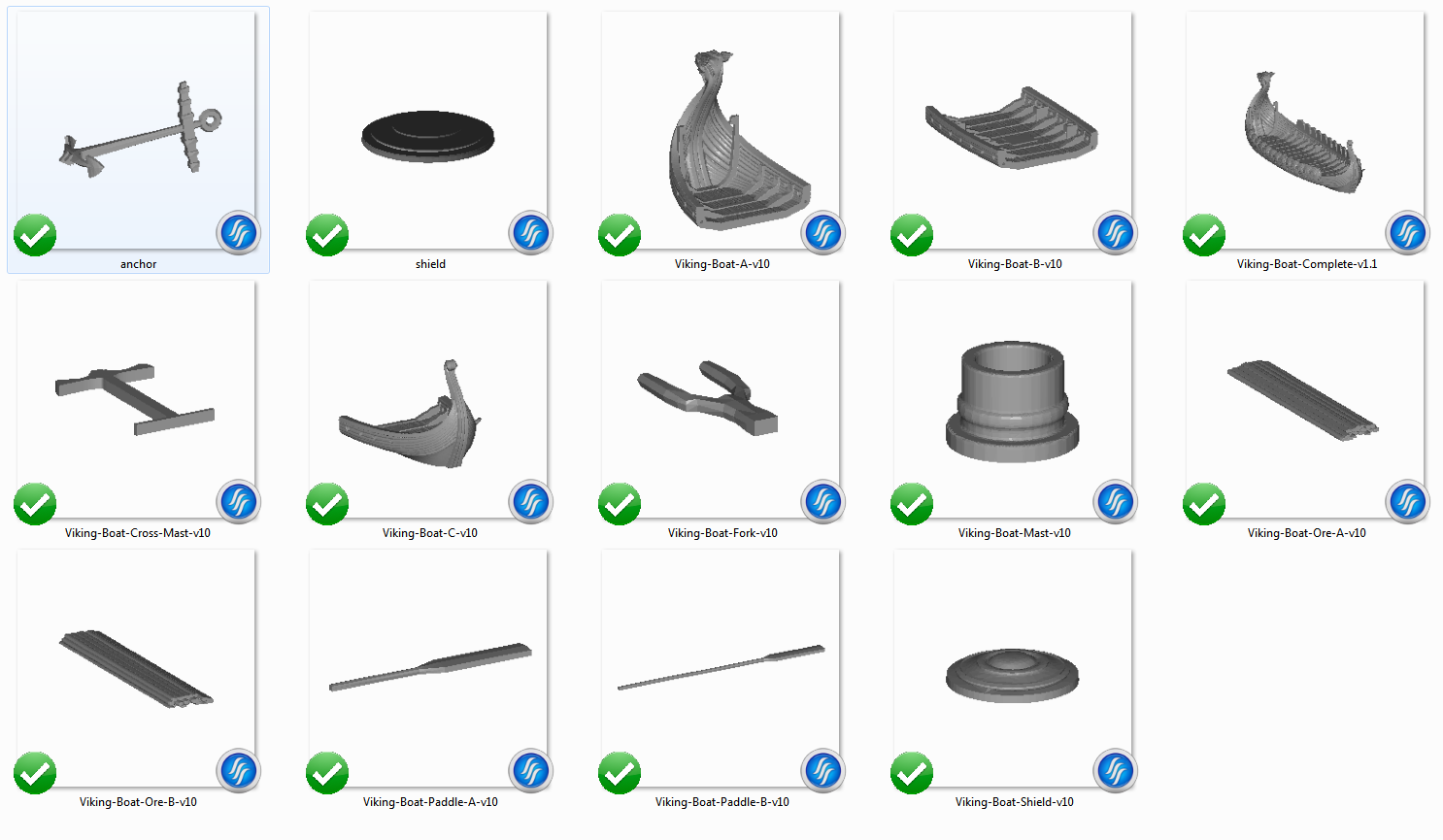

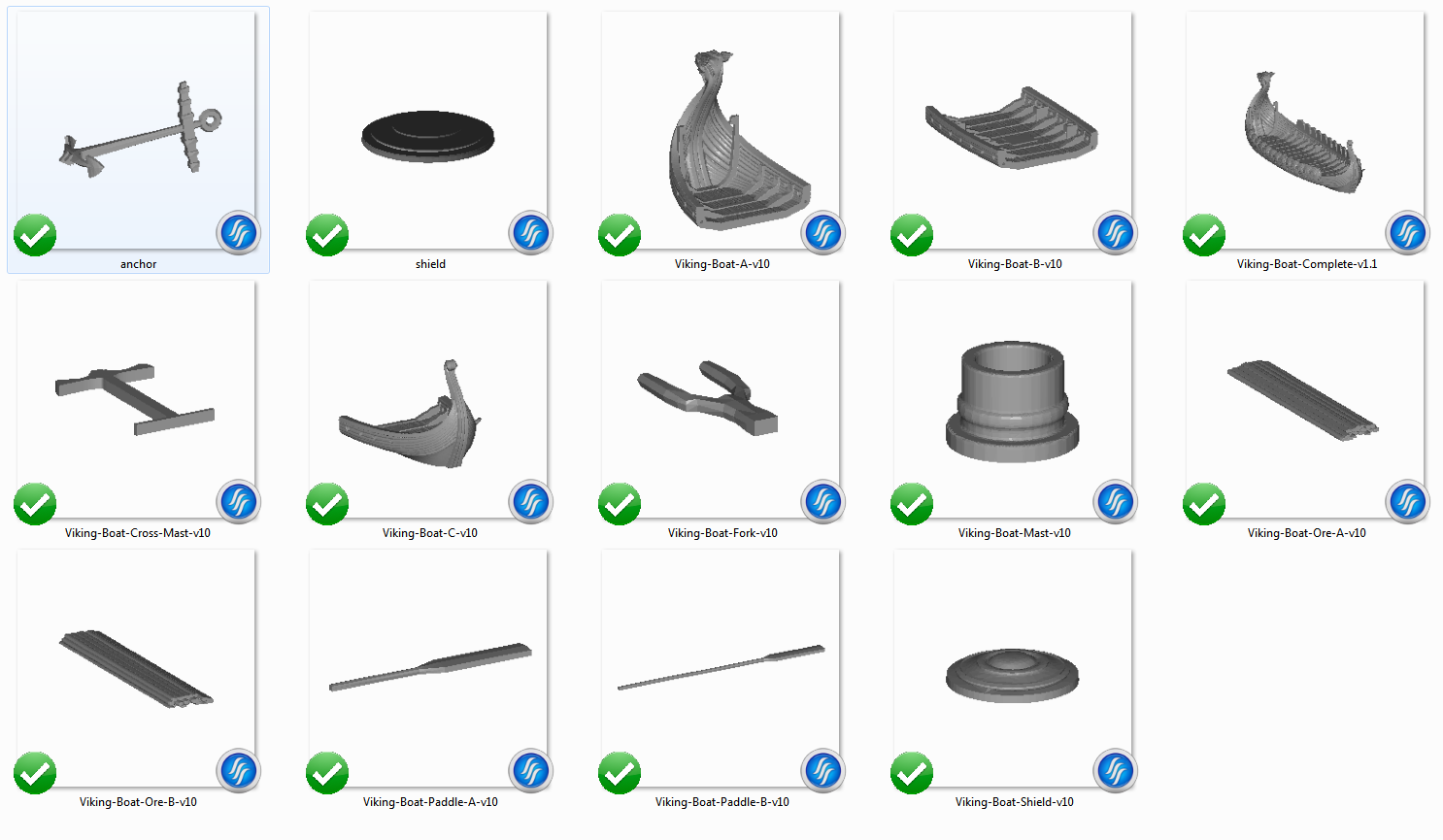

Updates:

- 10 July 2017 (version 1.1) Small mesh repair to Viking-Boat-Complete-v1.1.

Notes for Viking Longship:

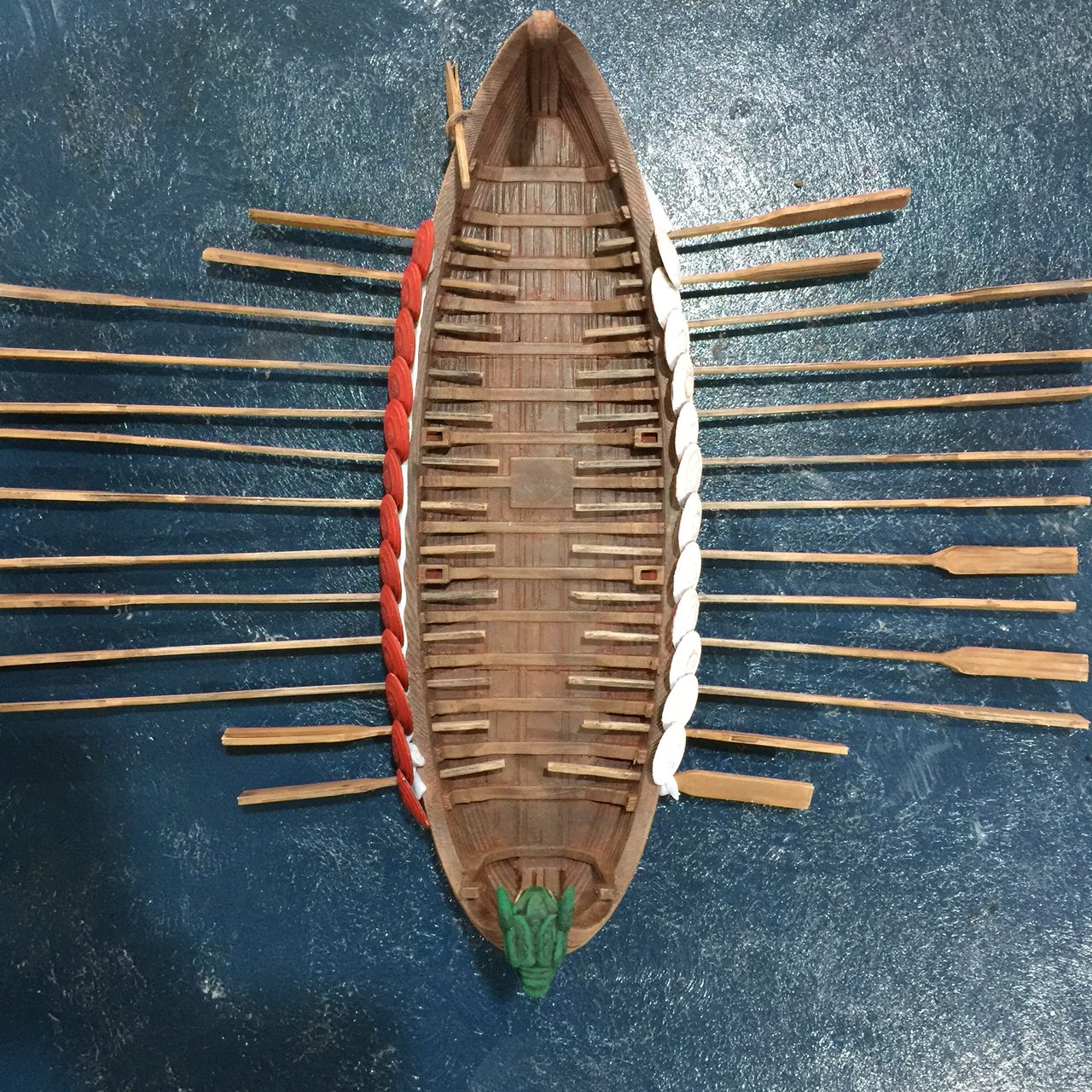

- Right-click on the image below and “Save As” to download the reference sheet for this pack.

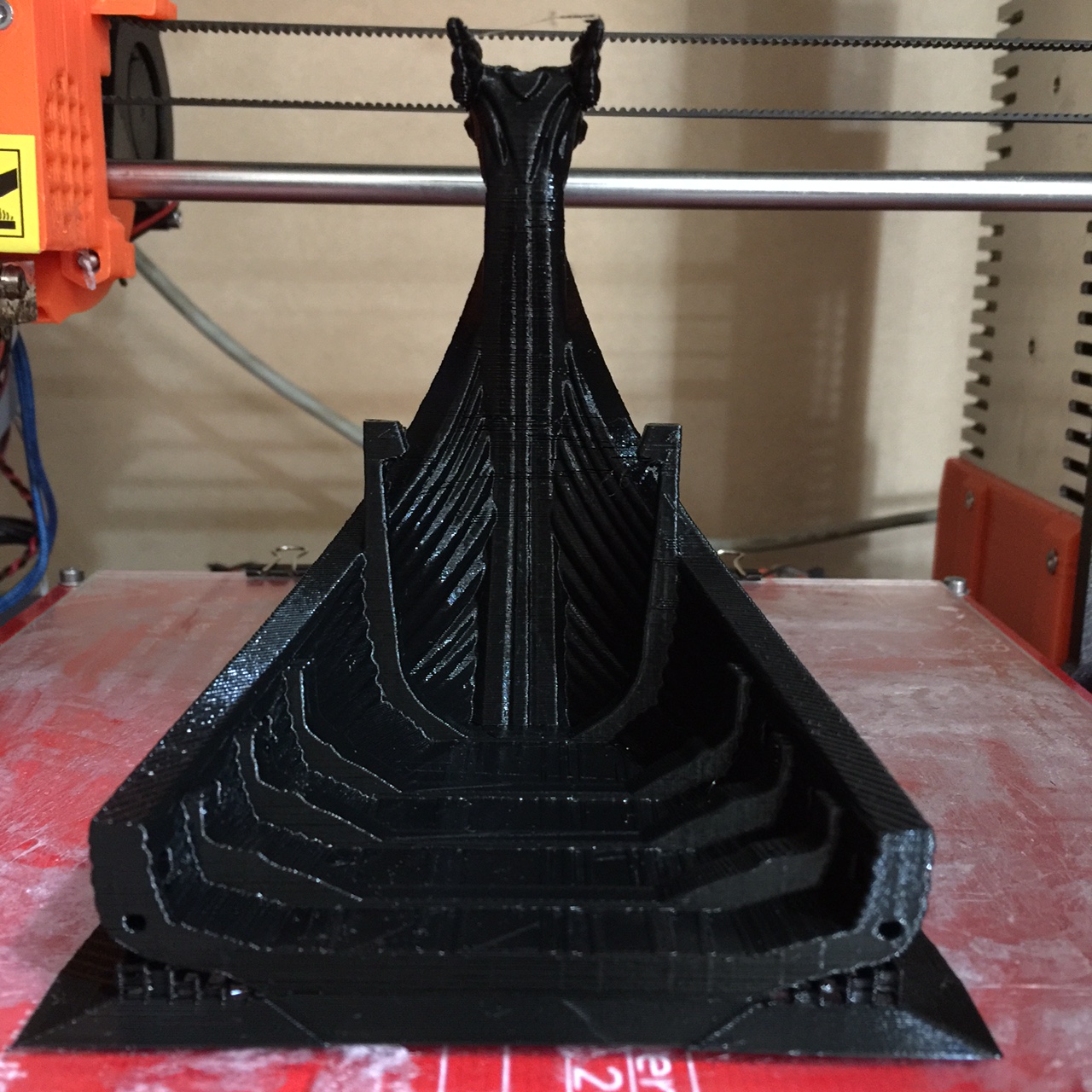

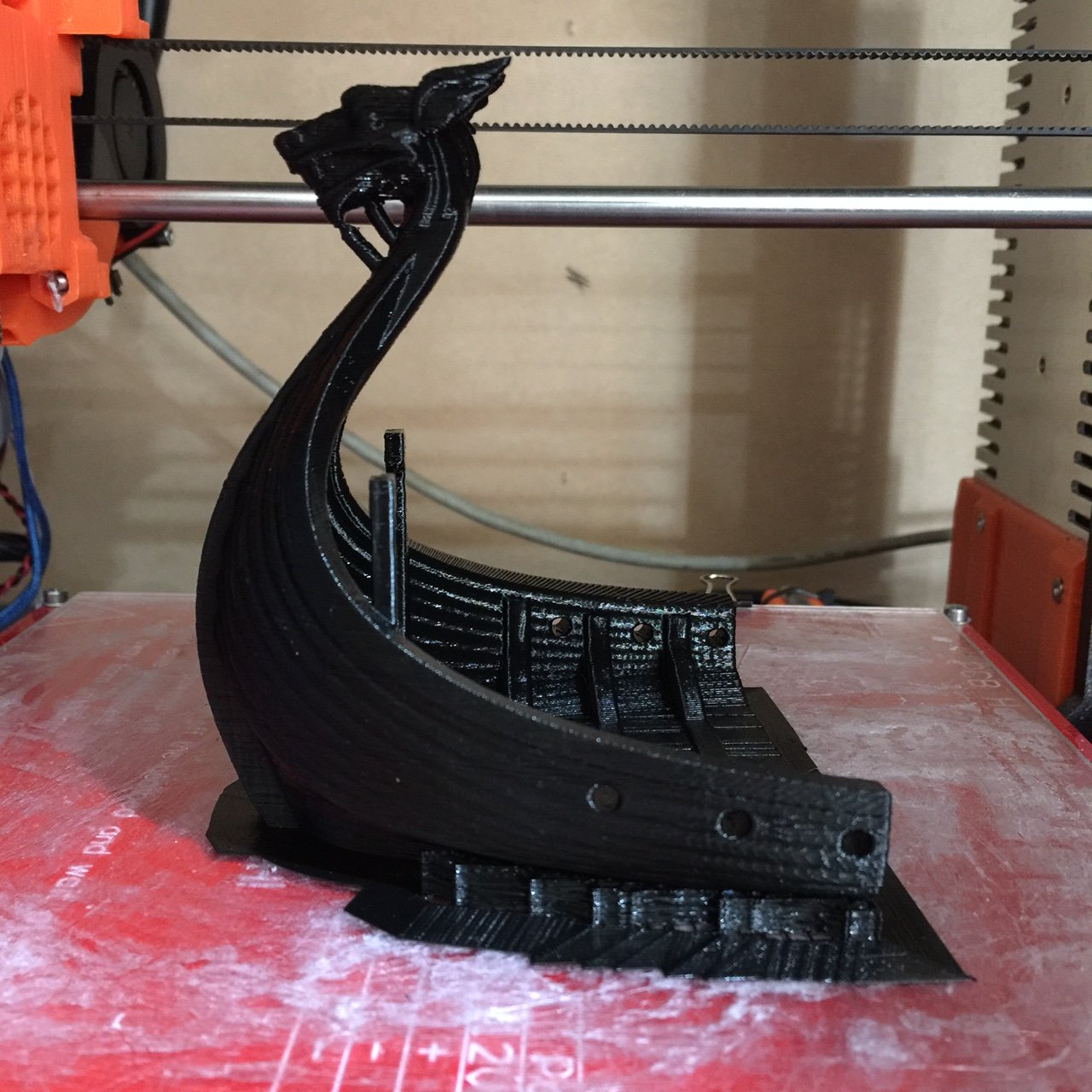

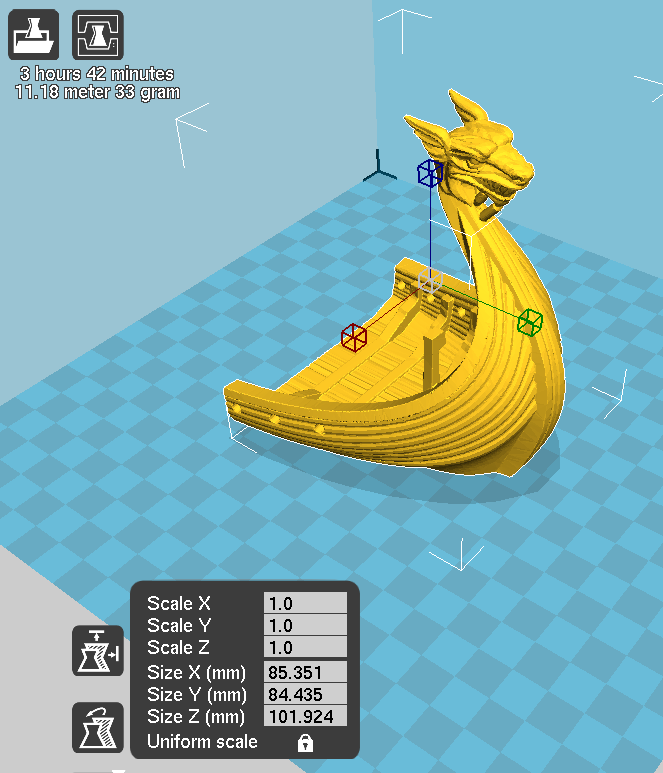

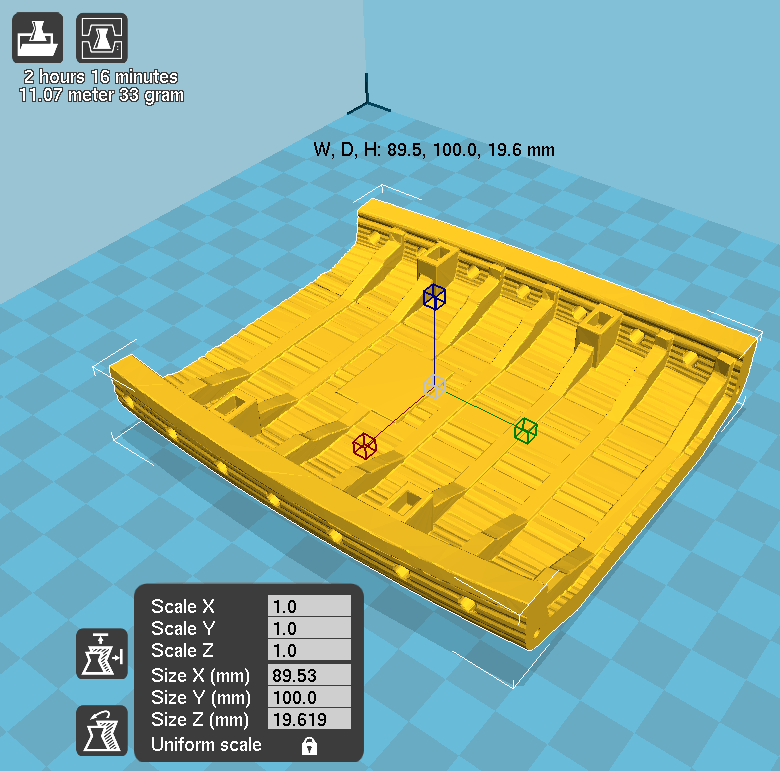

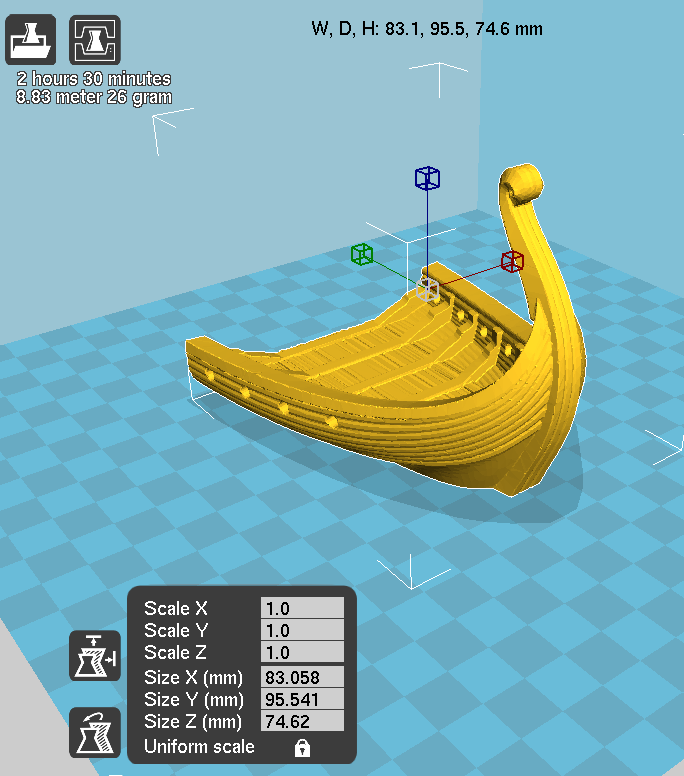

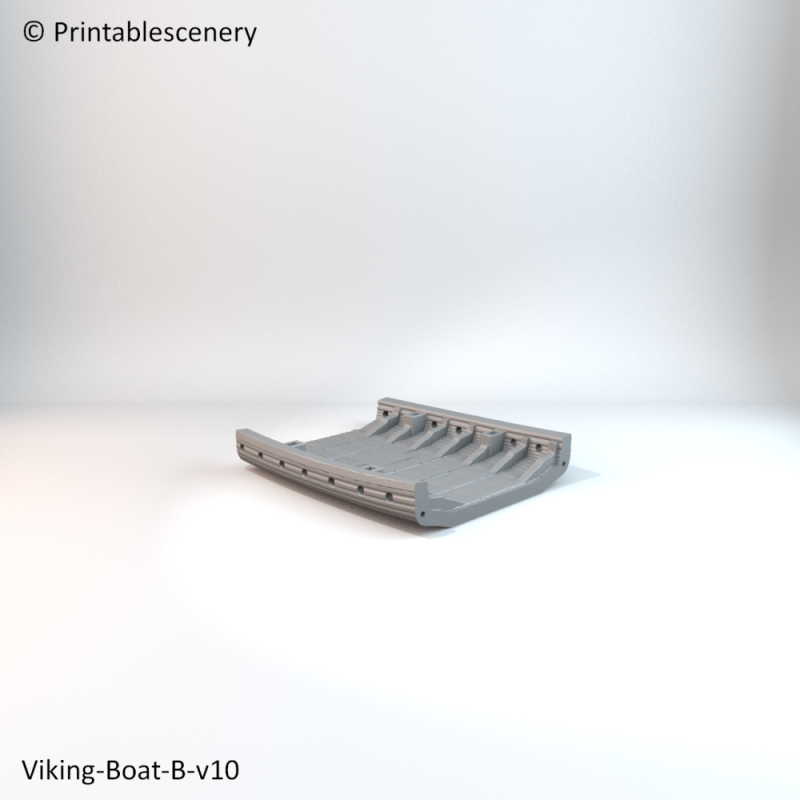

- Product measurements can be found in the image gallery.

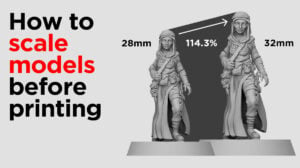

Use this tool to find the percentage needed to scale your model up or down when printing.

The highlighted row shows the model's current scale and other rows show what percentage to print at to reach that scale.

To set a custom scale, use the calculator in the bottom row.

- mm is the height based on the measurement from the bottom of the feet to the eye height of the average human

- Height is not the same as Base Size (A 28mm miniature will often have a 25mm round base)

Matthew Barker –

Ask any questions and you will be rewarded with answers

Jason Winter (verified owner) –

What is the air-speed velocity of an unladen swallow?

Matthew Barker –

about 24 miles per hour

alaalamsa –

hi,

how can i join the parts?

Matthew Barker –

Hi, There are guide holes in the model parts, you can use a piece of 1.75mm filament to join the parts.

You will need to glue the parts togeather. For ABS use Acetone to make glue from ABS offcuts, for PLA use Chloroform. You can also use superglue.

billlawrence01 –

Will it actually float?

Matthew Barker –

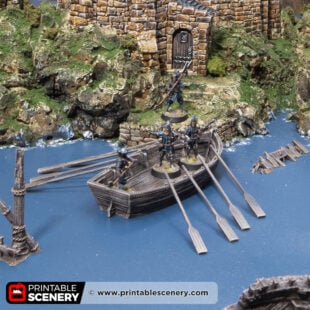

No, it has a flat bottom for game use, so it will capsize in the water.

Paul (verified owner) –

Could you make one with a hull?

Matthew Barker –

At this stage were only making ‘game ready’ versions of the ships. We could look at it at a later stage though

Scott –

I see there might be an option to place a mast. Do you have recommendations for a mast?

Matthew Barker –

We normally use a wooden dowel for the masts. You can scale the mast stand separately to fit any size dowel.

Cameron Hanson (verified owner) –

just wondering if I’m doing something wrong. first time printing this ship, I left settings at default (exception of printing at 110%) description says it should print without supports I’m using a Bambu P1S. front and back started printing fine but the mid-section was printing 1mm off the edge of previous layer causing it to fail fortunately i caught it before it went to far.

Joanne Boorer (verified owner) –

Hi Cameron, I have increased the size to 110% and is still sitting flat on the build plate of our Bambu P1P.

Does it show in your slicer as being flat on the buildplate? Also are you printing with a brim or raft?

Cameron Hanson (verified owner) –

Thanks for your response Joanne. yes, it was sitting flat on the plate and had good adhesion the printer is only a few weeks old and I level the bed on almost every print. it’s my first printer so I had to look up what brims and rafts where, no, I wasn’t using them. I printed with auto supports and got a mostly successful print, some repair work needed to smooth out the underside overhang.